Governor, Board of Public Works Announces Innovation-Focused Partnership

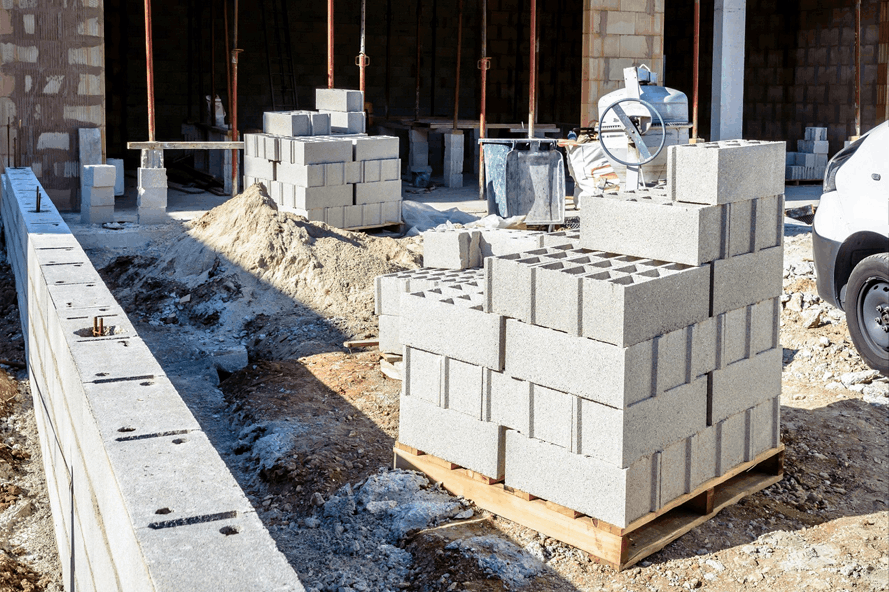

On January 27, 2021, Maryland’s Governor Larry Hogan and Board of Public Works (BPW) approved a contract award to Susquehanna Concrete Products Inc. (“Suscon Products”), to study and demonstrate the innovative reuse of dredged material sediment to manufacture certain products for use in construction. This includes production of general use concrete products, such as retainer walls and low-compression strength blocks. The award has been made in response to the Request for Proposals for Research & Development projects to advance innovative reuse as specified in the updated Innovative Reuse & Beneficial Use Strategy from the Maryland Department of the Environment (MDE).

“Given our company’s strong history in the precast industry and dedication to innovation, our management team is confident that Suscon Products represents an ideal partner to work with the Maryland Port Administration on its mission to identify innovative and beneficial reuse opportunities for dredge material,” said Suscon Products President Miguel Lambert.

The contract approved by the Maryland Department of Transportation’s Maryland Port Administration (MDOT MPA), BPW and Maryland Port Commission (MPC) could greatly expand ways to reuse dredged material. Dredge sediment gathers in shipping channels and must be routinely cleared to keep lanes open for ship navigation. Also, dredge material must be excavated from the Port of Baltimore to increase its future capacity and ability to accept vessels of various sizes. In the past, the sediment byproduct has been used for land restoration. Projects to restore Hart-Miller Island in Baltimore County and Poplar Island in Talbot County have utilized dredged material, and James and Barren islands in Dorchester County are slated to be rebuilt over the next several years using dredged sediment.

“Unbeknownst to most, the State of Maryland has a real need to develop innovative reuses of dredge material as it plans to maintain and expand the Port of Baltimore Port capacity and bolster the State’s transportation industry. We believe we can put that material to productive use,” said Suscon Products General Counsel Ano Mugwagwa.

In a previous press release from MPA, Governor Larry Hogan said, “Our administration is pleased to see companies explore ways to transform dredged material into products that aid construction and boost our economy. These innovative uses could turn sediment that builds up in the Chesapeake Bay into a valuable resource for making bricks, concrete and even structural support for shorelines.”

This contract will use dredge material from the MDOT MPA’s Cox Creek Dredged Material Containment Facility located just outside Baltimore. If successful, the contract could result in future or long-term opportunities to continue working with MDOT MPA to use dredge material sediment for innovative reuses and help contribute to the State’s sustainable material goals. Furthermore, it will help create jobs and add to Maryland’s reputation for driving innovation.

Suscon Products is pleased to have the support of MDOT MPA and other various state agencies and groups, including Department of Commerce and Sustainable Materials Management Maryland (SM3), towards its mission to develop innovative reuses of dredge material. MDOT MPA has been a national leader in using dredge material in ways that benefit the community and the environment,” MDOT Secretary Greg Slater said. “We’ve used this sediment for years to rebuild islands, create wildlife habitats and reinforce shorelines. These new proposals could lead to new and innovative reuse of dredged materials.”

The objectives of this project are to conduct a preliminary analysis of the efficacy and feasibility of using dredge material to enhance or replace any materials used to manufacture concrete. If the findings are positive, Suscon Products will establish mix-designs and initial scalable operations for the innovative reuse of dredge material for manufacturing concrete products.

Founded in 1969, Suscon Products has a rich history of innovation and manufacturing complex precast products serving industrial, commercial, and multifamily residential customers. The Company is located at 42 Fort Hoyle Road in Harford County, Maryland. Originally, Suscon Products was established to primarily manufacture precast concrete products, mainly chimneys and smoke stakes. The company gained national recognition in this space with its nationally registered UL listing and has even supplied its products to customers and projects in various states, including Maryland, New York, Ohio, and Oklahoma, among others.

After a reorganization in January 2018, the manufacturer made a significant investment in upgrading the plant and operations to revitalize the company and focus on improving the production process, product quality, manufacturing efficiency and capacity as well as diversifying the product offerings manufactured at the plant. Utilizing readymix concrete, the company currently supplies an assortment of products for industrial, commercial, and residential application, such as chimney stacks, refractors, retainer walls, columns, steps, and caps, among other products.